| # | Name | Points |

|---|---|---|

| 1 | Arun Teja | 7150 |

| 2 | Vadlamuri Sohan Aravind | 7125 |

| 3 | Venkateshwaran T | 7040 |

| 4 | Logavignesh M | 6250 |

| 5 | Mandeep Singh Thakur | 6065 |

| # | Title | Points | Date |

|---|---|---|---|

| 1 | Login | 5 | 08-Feb-2025 14:45:00 |

| 2 | Login | 5 | 27-Dec-2024 19:37:05 |

| 3 | Assignment | 30 | 28-Oct-2024 11:20:31 |

| 4 | Login | 5 | 28-Oct-2024 08:27:16 |

| 5 | Assignment | 30 | 25-Oct-2024 12:33:48 |

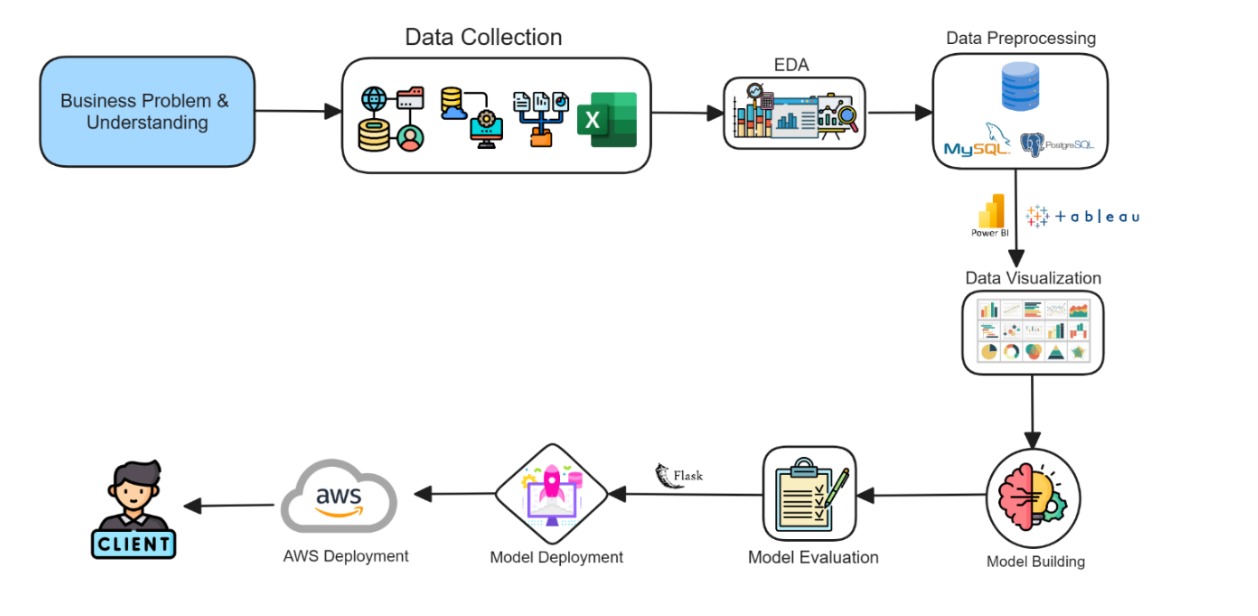

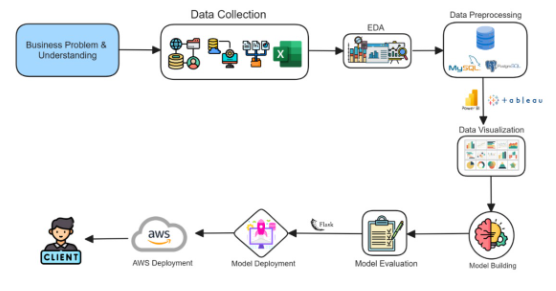

Dive deep into our groundbreaking projects that redefine industry standards.

Explore Our Projects

Delve into our extensive portfolio of innovative projects that span multiple industries and harness the transformative powers of AI and digital technologies. From healthcare to manufacturing, our solutions address real-world problems with precision, efficiency, and scalability.

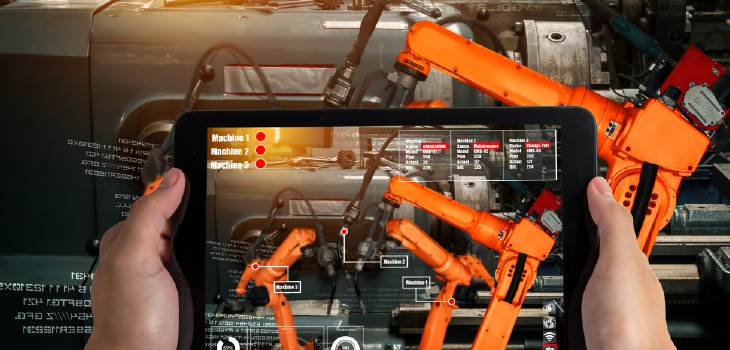

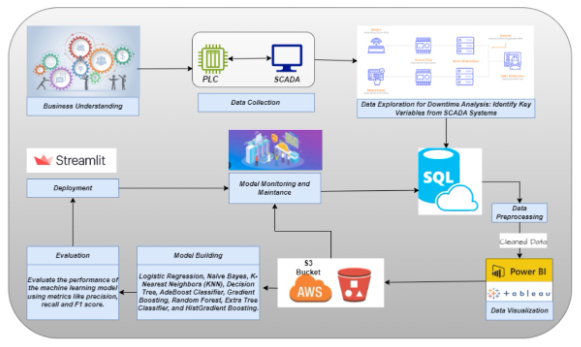

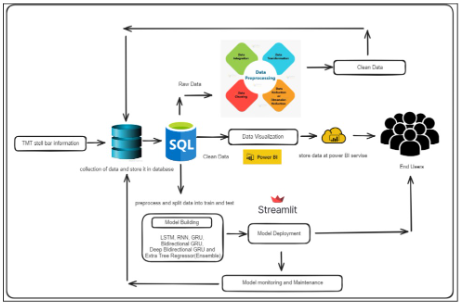

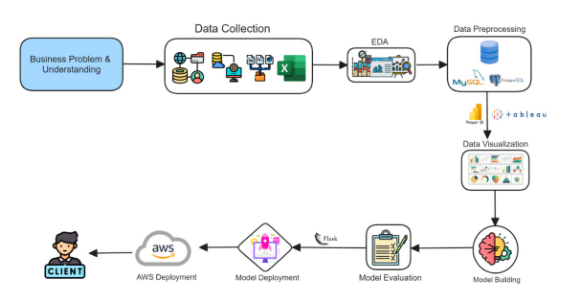

The efficiency and longevity of industrial equipment are paramount in manufacturing settings. PRIMA 13, a crucial apparatus for steel rod cutting and bending, significantly influences the production flow. Unexpected breakdowns of PRIMA 13 can induce production halts, financial setbacks, and probable interruptions in delivering to clients.

Problem Statement: Construct a predictive maintenance algorithm utilizing machine learning to forecast possible malfunctions in the PRIMA 13 steel rod cutting and bending machine. This would aim to reduce unforeseen downtimes, boost operational effectiveness, and ensure maintenance is carried out in a timely manner.

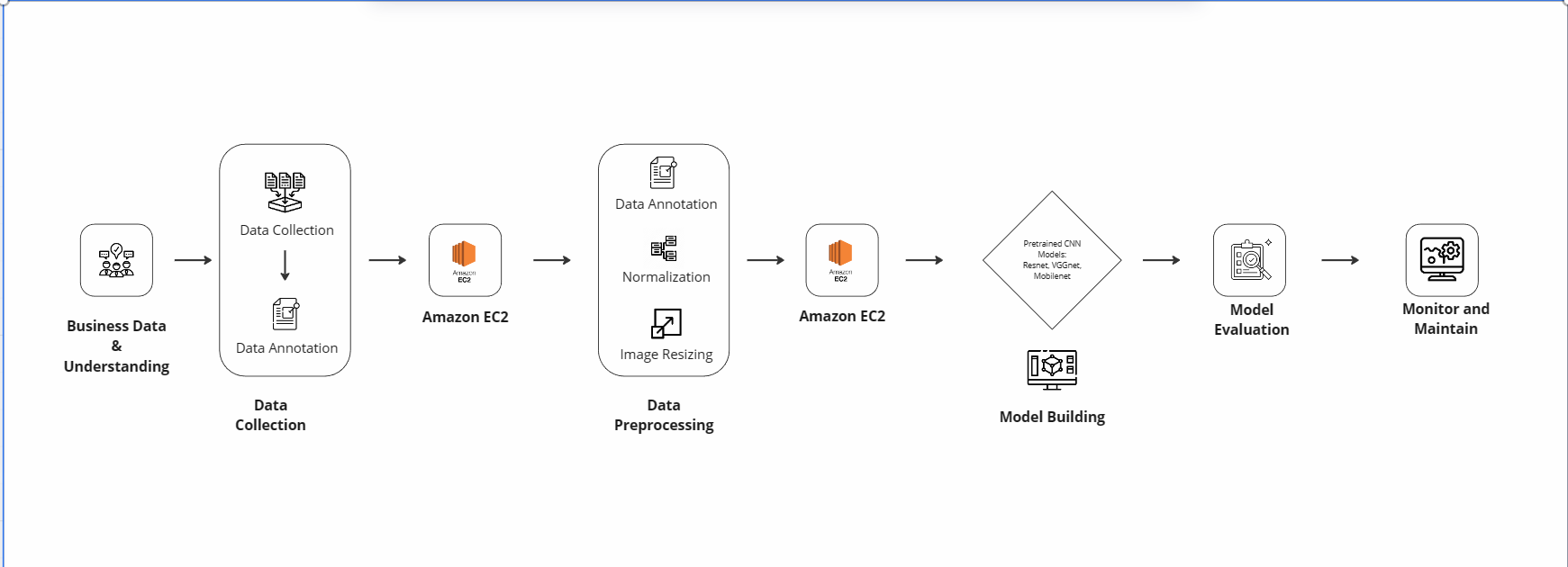

In the fast-paced cement manufacturing sector, ensuring consistent product quality is paramount. A leading cement manufacturer grapples with the challenge posed by the current manual quality inspection process, which is conducted hourly. This method is not only inefficient but also leads to significant product wastage if quality issues arise between inspections. The resultant downtime for machine inspection and maintenance, coupled with the disposal of substandard cement, escalates production costs, impacts revenue, and risks failing to meet market demand.

Problem Statement: To address the inefficiencies and limitations of manual hourly cement quality inspections, there is an urgent need for an automated quality inspection system. This system must be capable of monitoring cement quality continuously in real-time, promptly identifying any production issues, and facilitating immediate corrective action. By doing so, the project aims to minimize manual intervention, reduce cement wastage, and enhance operational efficiency and profitability.

In the competitive vehicle fuel pump manufacturing industry, operational efficiency is crucial for maintaining market leadership and delivering high-quality products cost-effectively. A significant challenge impacting the client’s production efficiency is unplanned machine downtime within their manufacturing processes. These unforeseen interruptions not only hamper productivity but also result in financial losses due to halted production lines and delayed order fulfillment.

Problem Statement: To uphold its commitment to efficiency and quality, the client seeks to address the issue of unplanned machine downtime through technological innovation. The goal is to implement a predictive maintenance system that can foresee potential equipment failures and schedule maintenance proactively. By doing so, the project aims to minimize unexpected production stoppages, enhance equipment efficiency, and reduce maintenance costs.

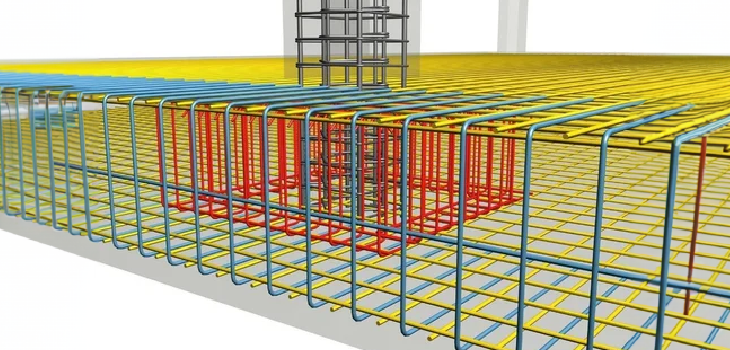

The construction sector in India faces significant challenges in planning and executing building structures, primarily due to the manual and error-prone process of creating bar bending schedules (BBS). These challenges not only result in delays and increased costs but also contribute to substantial material wastage. There's an urgent need to enhance the efficiency and accuracy of this process to meet the growing demands of the industry.

Problem Statement: To address these inefficiencies, our project proposes the introduction of an innovative, AI-driven solution designed to automate the generation of bar bending schedules. This technology aims to streamline the construction planning phase, ensuring precise calculation of BBS fields according to the Bureau of Indian Standards (BIS) and the National Building Code of India (NBC). By doing so, we anticipate a significant reduction in time, cost, and material wastage, ultimately elevating the construction process in India.

The steel manufacturing industry frequently faces the challenge of underutilizing offcuts, which are remnants from steel rods cut to size. These offcuts, often regarded as waste, are sold as scrap, resulting in a considerable loss of potential revenue. The current approach not only impacts profitability but also deviates from sustainable manufacturing practices by not maximizing the use of all resources.

Problem Statement: In an era where efficiency and sustainability are paramount, the prevalent practice of underutilizing steel rod offcuts and relegating them to scrap status represents a significant financial and environmental oversight. The project seeks to revolutionize this aspect of operations by leveraging advanced machine learning algorithms and automation technologies. The goal is to enhance the utilization rate of these offcuts, thereby reducing waste, increasing revenue, and aligning with eco-friendly practices.

The energy sector is increasingly reliant on wind power as a clean and renewable source of electricity. However, the unplanned failure of wind turbine engines poses a significant challenge, resulting in considerable financial losses and a detrimental impact on electricity production. These failures disrupt the continuous generation of power and necessitate costly repairs and replacements, straining operational budgets and reducing overall efficiency.

Problem Statement: In light of the critical role wind turbines play in sustainable energy production, there is an urgent need to enhance the reliability and efficiency of these machines. The project aims to drastically reduce the incidence of unplanned turbine failures by implementing a system of proactive maintenance and advanced monitoring. By accurately predicting potential failures before they occur, the project seeks to facilitate timely interventions, thereby minimizing downtime and ensuring uninterrupted electricity generation.

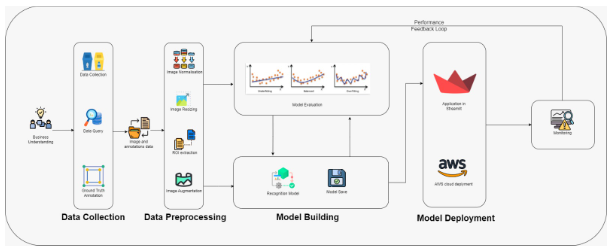

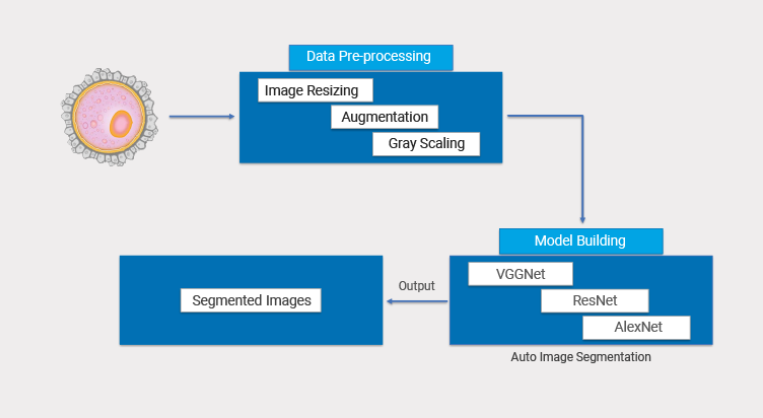

The world of In Vitro Fertilization (IVF) is delicate, holding significant impact on countless individuals and couples who aspire to have a child. An integral component of this process is the accurate identification and selection of viable embryos. Traditional techniques rely heavily on human judgment, bringing in elements of subjectivity and potential inaccuracies. These inefficiencies can lead to reduced IVF success rates, posing emotional and financial burdens on hopeful parents.

Problem Statement: To bolster IVF success rates and alleviate strains on both medical professionals and patients, there's a pressing need to introduce an advanced AI-driven model. This model should offer precision in assessing embryo viability, thereby streamlining resource allocation in embryology labs and elevating the chances of successful implantation.

The world of In Vitro Fertilization (IVF) is delicate, holding significant impact on countless individuals and couples who aspire to have a child. An integral component of this process is the accurate identification and selection of viable embryos. Traditional techniques rely heavily on human judgment, bringing in elements of subjectivity and potential inaccuracies. These inefficiencies can lead to reduced IVF success rates, posing emotional and financial burdens on hopeful parents.

Problem Statement: To bolster IVF success rates and alleviate strains on both medical professionals and patients, there's a pressing need to introduce an advanced AI-driven model. This model should offer precision in assessing embryo viability, thereby streamlining resource allocation in embryology labs and elevating the chances of successful implantation.

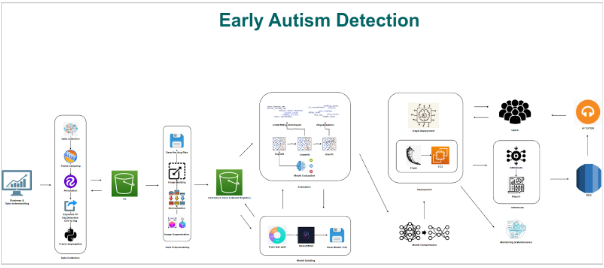

Autism Spectrum Disorder (ASD) remains significantly undetected in its early stages, posing a growing concern as behaviors associated with autism in children become more prevalent. Early detection is critical in initiating timely interventions that can greatly improve the quality of life for affected children and their families.

Problem Description: This project aims to serve all children by utilizing advanced AI-driven models to detect autism-related behaviors early. By identifying these behaviors promptly, the project seeks to facilitate early intervention treatments, which are crucial in helping children manage or significantly reduce the impact of ASD on their lives.

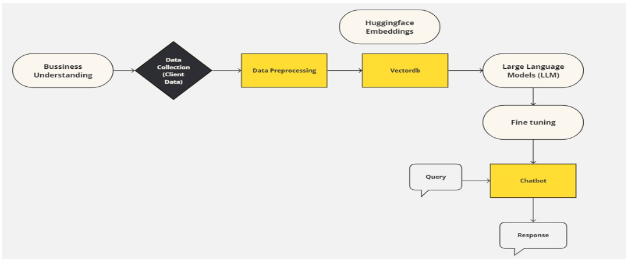

In the pharmaceutical industry, accessing comprehensive data on medication prices, regulatory controls, and the latest market entries poses a significant challenge due to the vast and continuously evolving nature of this information. The lack of centralized, easily accessible databases makes it difficult for healthcare professionals, patients, and stakeholders to make informed decisions, impacting healthcare efficiency and the transparency of pharmaceutical pricing and regulations.

Problem Statement: To streamline healthcare decision-making and promote transparency in the pharmaceutical industry, there is an urgent need for a centralized solution that facilitates easy access to extensive pharmaceutical data. This solution must provide up-to-date information on medication prices, regulatory controls, and details on both established and newly emerging drugs in the market, thereby enabling informed choices and optimizing healthcare efficiency.

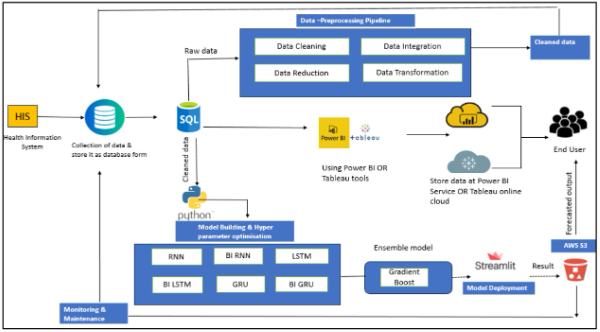

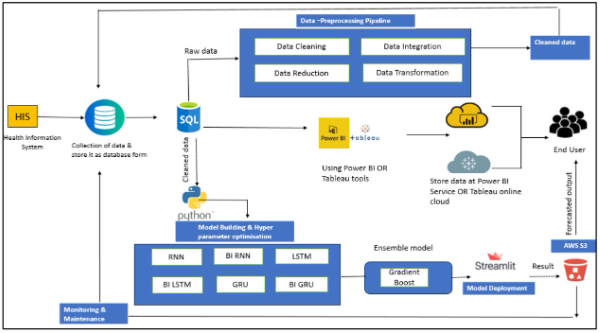

The healthcare sector is facing a significant challenge with increasing bounce rates, leading to patient dissatisfaction. This issue is partly attributed to the unavailability of essential medical supplies when needed, causing delays in treatment and negatively impacting patient trust and the hospital's reputation.

Problem Statement: To combat rising bounce rates and enhance patient satisfaction, this project proposes a strategic approach to medical inventory management. Leveraging machine learning algorithms, the goal is to optimize inventory levels, ensuring the timely availability of necessary medical supplies without incurring excessive inventory costs. By doing so, the project aims to reduce patient wait times, improve treatment efficiency, and ultimately decrease bounce rates.

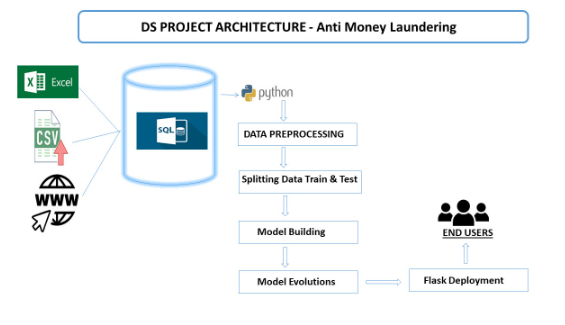

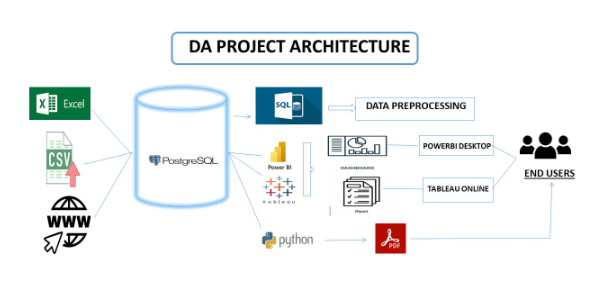

The client's operations are being compromised by a high frequency of fraud transactions that are slipping through undetected, leading to substantial financial losses. These fraudulent activities not only drain resources but also threaten to tarnish the client's reputation and undermine their financial health.

Problem Statement: There is an urgent necessity to mitigate the prevalence of fraudulent transactions within the client's systems to stave off the financial drain and protect the organization's credibility. The deployment of an advanced, AI-driven solution is required to enhance the detection and prevention of such activities effectively.

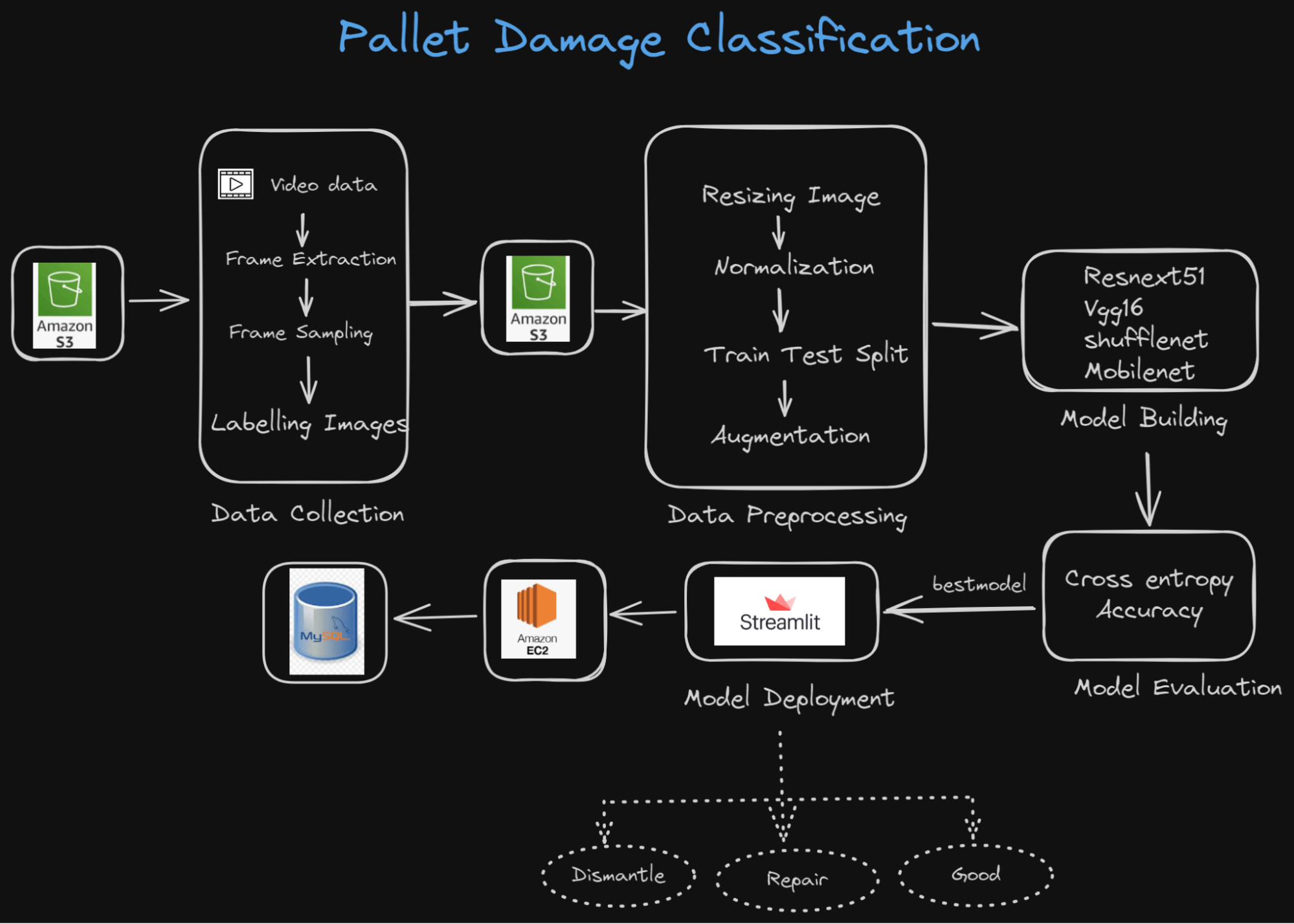

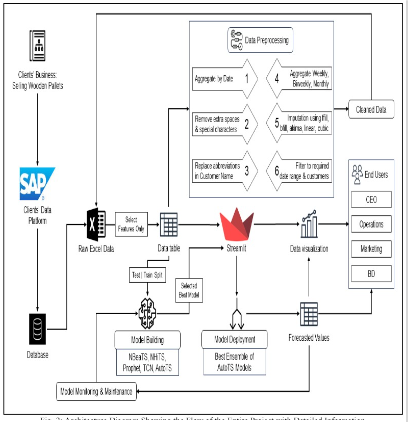

Effective warehouse management is paramount for supply chain efficiency. Pallets, being fundamental to this, when damaged, can jeopardize the integrity of goods, cause safety concerns, and lead to operational inefficiencies. Automating the detection and classification of pallet damage is crucial in addressing these concerns.

Problem Statement: Design and deploy an AI-driven system to autonomously detect and categorize pallet damages, aiming to safeguard goods' quality, enhance safety protocols, and boost operational fluency in warehouse and logistics settings.

The client, a prominent manufacturer and supplier of wooden pallets to major companies like Amazon, Flipkart, and Coca Cola, faces significant challenges with unnoticed pallet damages within their inventory. The inadvertent shipment of these damaged pallets to customers not only leads to dissatisfaction but also incurs additional costs due to returns and unnecessary travel for the damaged goods. This inefficiency in the damage detection process undermines customer trust and escalates operational costs.

Problem Statement: To address the issue of unnoticed pallet damages and improve customer satisfaction, the client seeks to implement a sophisticated damage detection and classification system. Utilizing deep-learning models, the project aims to accurately classify wooden pallets into categories: good, repair, and dismantle. This technological solution intends to minimize manual inspection efforts, streamline inventory management, and ensure only quality pallets are delivered to customers.

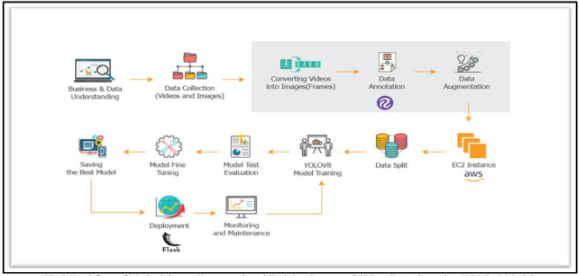

In industrial and warehouse settings, the manual process of counting pallets is not only labor-intensive but also susceptible to errors, which can lead to significant operational inefficiencies. These inaccuracies necessitate frequent recounts and adjustments, impacting workflow, delaying shipments, and incurring additional labor costs.

Problem Statement: To revolutionize warehouse operations and significantly improve the efficiency and accuracy of pallet counting, this project proposes the adoption of YOLOv8, an advanced deep learning object detection algorithm. By automating pallet detection and counting through a custom-trained YOLOv8 model, the project aims to minimize human intervention, reduce error rates, and enhance overall operational productivity.

The dynamic nature of customer demands and the subsequent volatility in inventory levels pose significant challenges for warehouse operations. This volatility results in frequent understocking or overstocking situations. Understocking leads to unmet client requirements, jeopardizing customer relationships and potential revenue, while overstocking incurs unnecessary inventory costs, reducing overall operational efficiency.

Problem Statement: This initiative aims to revolutionize warehouse management by implementing an AI-driven system designed to accurately predict inventory needs, thus ensuring optimal stock levels are maintained. By leveraging advanced analytics and machine learning techniques, the project seeks to anticipate customer demand with high precision, enabling proactive inventory adjustments. This approach not only aims to minimize storage costs but also ensures that customer demands are met promptly, enhancing satisfaction and loyalty.

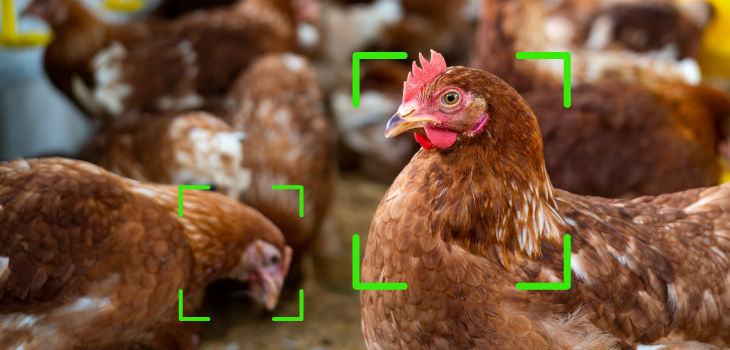

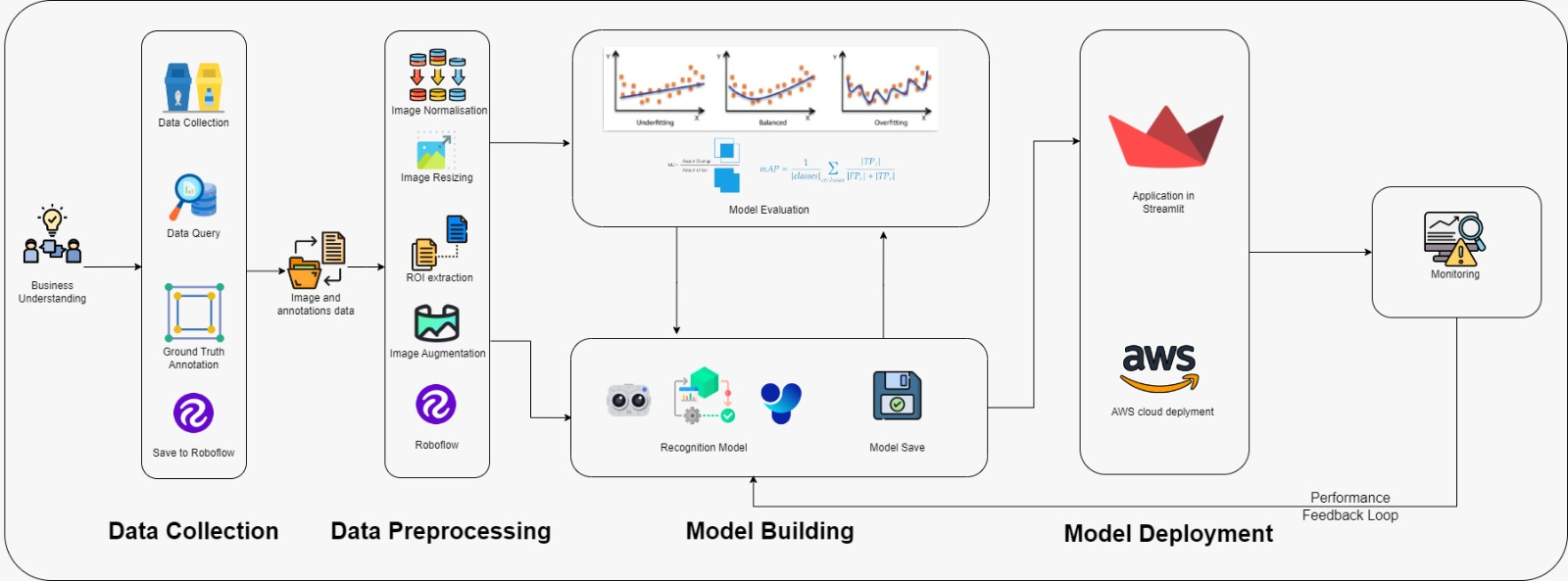

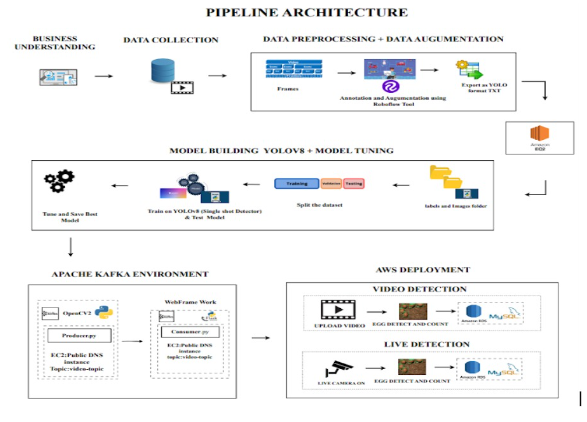

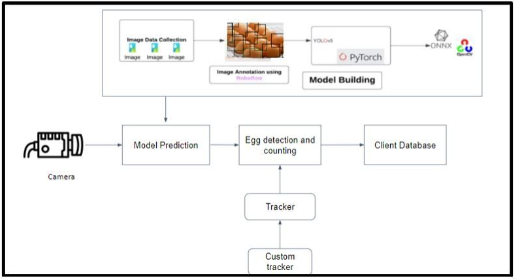

In poultry farms, particularly those specialized in egg production, efficient management and quality control of produced eggs are essential for both profitability and brand reputation. Relying on manual counting and quality inspection of eggs presents challenges due to being labor-intensive and error-prone.

Problem Statement: To devise an artificial intelligence solution that automates the egg counting, color differentiation, crack detection, and stain identification processes as they transpire on a conveyor belt. This will ensure accurate inventory management and stringent quality assurance in a high-paced environment.

In the realm of poultry farming, optimal chick growth conditions are paramount for their health and subsequent productivity. Central to this is the ability to accurately determine a chick's age and monitor its body temperature. Proper management in these areas directly influences feeding, healthcare, and overall environmental control.

Problem Statement: Create an integrated solution that harnesses the power of machine learning coupled with sensor technology. This will serve to ascertain the age of chicks with precision and keep a constant check on their body temperature. The ultimate aim is to ensure that poultry farms consistently offer the most conducive conditions for chick growth.

Ineffective waste management practices are prevalent due to challenges in accurately identifying and segregating non-biodegradable materials from biodegradable waste. This issue leads to higher contamination in recycling processes, increased operational costs, and obstacles in efficient waste reduction.

Problem Statement: The core challenge is to enhance the efficiency of waste management systems by developing advanced methods for the precise identification and segregation of non-biodegradable materials within biodegradable waste. This improvement aims to reduce contamination in recycling streams, decrease processing expenses, and boost overall waste minimization efforts, fostering a more sustainable approach to waste management.

In the dynamic sphere of the poultry industry, particularly within India’s fast-paced market, the challenge of manually tracking poultry birds and the precise weight measurements of chicks poses a significant operational burden. This manual process is not only labor-intensive but also prone to errors, which can lead to inefficiencies and economic losses.

Problem Statement: To enhance the overall efficacy of the poultry supply chain and to alleviate the physical and logistical demands on the workforce, it is imperative to introduce a sophisticated AI-driven system. This system aims to automate the tracking and weighing of poultry, ensuring both accuracy and a reduction in manual labor.

In the competitive poultry industry, the manual process of sorting and counting eggs based on color (brown vs white) poses significant operational challenges. This labor-intensive task not only demands considerable time and effort from the workforce but also impacts the overall efficiency and productivity of the company. The need for a technological solution to address this issue is evident, aiming to reduce manual labor while ensuring cost-effectiveness.

Problem Statement: To significantly improve operational efficiency and reduce the reliance on manual labor in egg sorting and counting, this project aims to implement an automated system. By leveraging advanced machine learning algorithms, the project seeks to accurately and efficiently differentiate between brown and white eggs, streamlining the process and enhancing productivity. This solution is expected to offer substantial time and cost savings, contributing to the company's competitiveness and profitability.

In the competitive poultry industry, operational efficiency is paramount. A leading poultry services company in India faces a significant challenge: the laborious and time-consuming task of manually distinguishing and counting brown versus white eggs. This manual process not only strains resources but also slows down operations, affecting overall productivity and efficiency.

Problem Statement: To enhance operational efficiency and maintain cost-effectiveness, there is a critical need for an innovative solution that reduces the manual labor involved in the egg counting process. The aim is to leverage technology to accurately and efficiently differentiate and count brown and white eggs, thereby streamlining operations and improving cost efficiency for the company.

In the poultry industry, especially within operations providing comprehensive poultry services in India, the neglect of proper litter management creates an environment conducive to the buildup of pathogens and ammonia. Such conditions pose significant threats to the respiratory well-being of birds, escalate the risk of diseases, and ultimately undermine the overall success and sustainability of poultry enterprises.

Problem Statement: To secure and advance poultry health, it's imperative to tackle the critical challenge of litter management through technological innovation and machine learning. An efficient solution is required to mitigate the adverse effects of pathogen buildup and ammonia, thereby enhancing the welfare of poultry, reducing disease incidence, and fostering a more sustainable and profitable farming operation.

In the highly competitive job market, the ability to effectively communicate during interviews is paramount. However, many candidates struggle with expressing themselves clearly and confidently, negatively impacting their chances of securing employment. Issues such as a lack of smiling, improper voice modulation, and displaying insufficient confidence can lead to negative perceptions, regardless of the candidate's qualifications and potential for the role.

Problem Statement: To significantly enhance job prospects, there is an urgent need for a solution that provides AI-driven interview coaching. This solution must address nuanced aspects of communication, such as emotional expression, tone of voice, and clarity of speech, to empower candidates to present themselves in the best possible light. By improving these aspects, candidates can increase their likelihood of job success, overcoming the barrier of ineffective communication.

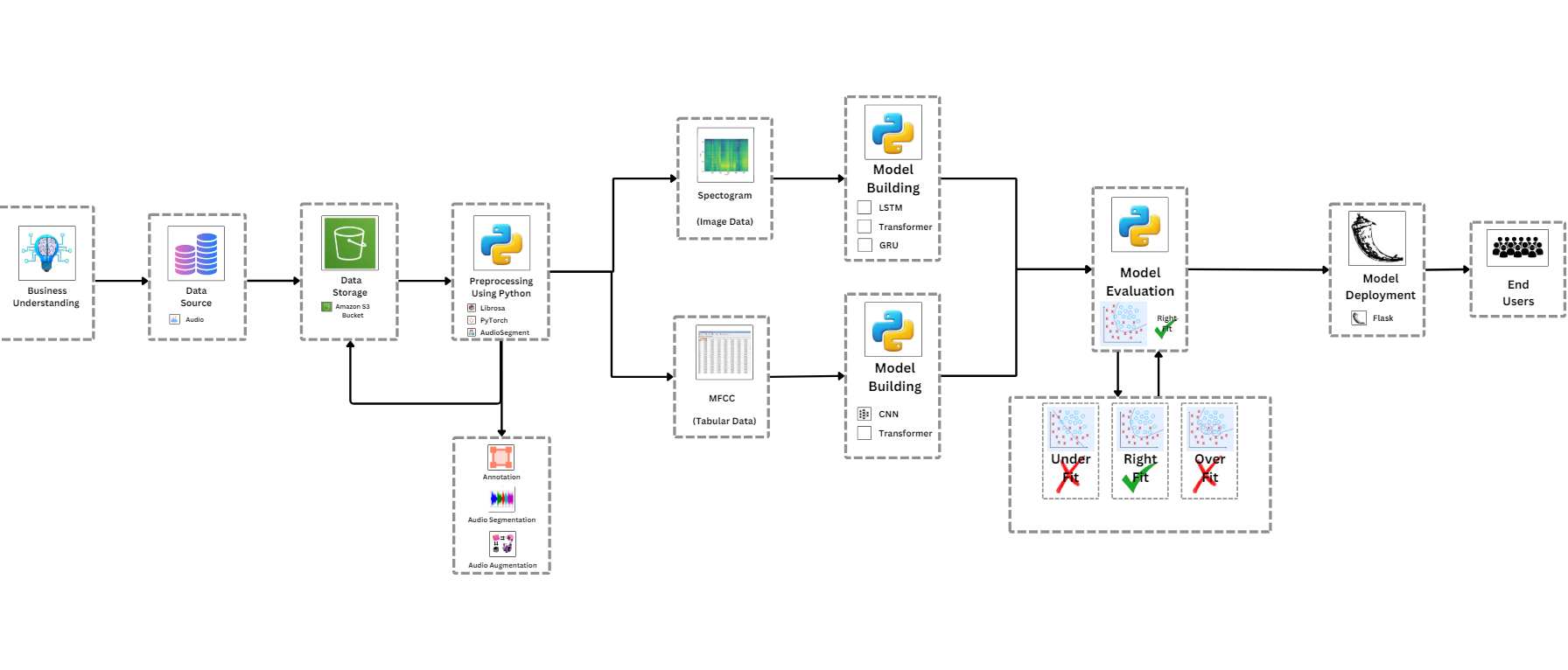

In the dynamic field of Education Technology (EdTech), a Malaysian startup has identified a significant challenge impacting the learning experience of students, especially non-native English speakers. The difficulty in comprehending the speech of tutors or teachers due to accent differences often leads to a diminished understanding of academic concepts, adversely affecting student outcomes.

Problem Statement: To bridge the communication gap between educators and non-native English-speaking students, there is an urgent need for a technological solution that transcends linguistic barriers. The project seeks to develop an Artificial Intelligence (AI)-powered Text-to-Speech (TTS) and Speech-to-Text (STT) application. This innovative approach aims to enhance the clarity and comprehensibility of educational content, thereby significantly improving learning outcomes for a diverse student population.

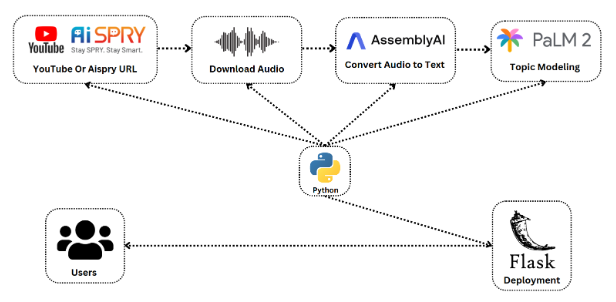

In the educational domain, particularly in online learning platforms like AiTutor, gauging student engagement and understanding during video lectures remains a significant challenge. The absence of a mechanism to track at what points students disengage or skip through the content leads to a gap in providing targeted feedback. Without insights into which topics or sections cause students to lose interest, educators and platforms cannot tailor their interventions to enhance understanding or retention effectively.

Problem Statement: To enhance the online learning experience and improve educational outcomes, there is a pressing need for an innovative solution that can analyze video engagement and identify specific topics that lead to student disengagement. By pinpointing the segments of video lectures that are frequently skipped, the system would enable personalized feedback, guiding students to revisit critical concepts they may have missed, thus fostering a more effective learning environment.

In the context of educational engagement, especially within online platforms such as AiTutor, a significant challenge lies in measuring student engagement and comprehension during video lectures. The lack of a system to identify when and why students disengage or skip content prevents the delivery of precise feedback. Without understanding which topics or sections lose student interest, educators and platforms are unable to customize their interventions to improve understanding or engagement effectively.

Problem Statement: To elevate the online learning experience and educational outcomes, it is crucial to devise a novel solution capable of analyzing video engagement and pinpointing the specific topics that cause student disengagement. By identifying the segments of video lectures that are frequently overlooked, the system could offer personalized feedback, urging students to review essential concepts they might have missed, thereby promoting a more effective learning environment.

A burgeoning startup within the healthcare sector is grappling with the challenge of stagnant website traffic. Despite providing valuable health-related services and information, the number of unique visitors to their website has not been growing as expected. This stagnation poses a significant barrier to expanding their reach and impact within the healthcare community.

Problem Statement: For a startup aiming to make a substantial impact in the healthcare domain, the website serves as a critical platform for disseminating information and offering services. The current plateau in website traffic growth limits the startup's potential to engage with a broader audience, thereby constraining its capacity to grow its user base and, by extension, its business. There's an essential need to revitalize the website's attractiveness and visibility to maximize unique visitor traffic while keeping marketing costs to a minimum.

In the realm of automotive manufacturing, the importance of adhering to a defined assembly sequence cannot be overstated. Any deviation in the clamping operations can have repercussions on the end product's quality and safety. Not only do these errors result in defective units, but they also cause increased rework, compromise safety standards, and disrupt production schedules.

Problem Statement: The challenge lies in addressing the incorrect clamping sequences that crop up during the automotive assembly process. Our solution leverages the power of AI to analyze video feeds, ensuring any deviation in the sequence is identified and rectified in real-time.

In the realm of automotive manufacturing, the importance of adhering to a defined assembly sequence cannot be overstated. Any deviation in the clamping operations can have repercussions on the end product's quality and safety. Not only do these errors ressult in defective units, but they also cause increased rework, compromise safety standards, and disrupt production schedules.

Problem Statement: The challenge lies in addressing the incorrect clamping sequences that crop up during the automotive assembly process. Our solution leverages the power of Al to analyze video feeds, ensuring any deviation in the sequence is identified and rectified in real-time.

A leading automotive manufacturer is encountering challenges in efficiently sourcing and delivering unique kit items from various vendors to meet specific customer demands. The manufacturer manages an inventory of automotive products, consisting of various vehicle parts, each uniquely assembled into kit items based on customer preferences. In a continuously fluctuating industry, maintaining customer satisfaction and timely delivery are paramount.

Problem Statement: To remain competitive and retain customer loyalty, the manufacturer needs an innovative solution that can forecast the demand for kit items more accurately and streamline the supply chain to reduce supply-demand discrepancies. This will enhance the delivery process, ensuring that customers receive their customized kits on time.

The construction industry stands at the forefront of modern urban development. However, a persistent challenge faced by this industry is ensuring the precise bending of reinforcing bars according to specified shapes and dimensions, as these play a pivotal role in the structural integrity of edifices. Manual interpretations of bar bending schedules (BBS) from architectural diagrams are time-consuming and prone to errors.

Problem Statement: To address this, there's an emerging need to employ Artificial Intelligence. The goal is to create an AI-driven system that leverages object detection techniques, enabling it to accurately decipher and extract the bar bending schedule from intricate construction architectural diagrams. This would assure the correct bending and strategic placement of the reinforcing bars, pivotal for the stability of structures.

In the bustling steel industry of Orissa, India, a significant challenge has emerged due to the manual counting of steel rods of various diameters (8 mm, 16 mm, 32 mm, etc.) within the inventory. This process is not only time-consuming but also fraught with errors, leading to inefficiencies and potential financial discrepancies in inventory management.

Problem Statement: To revolutionize the current manual and error-prone inventory management practices, there is a critical need for an automated steel rod counting system. Leveraging advanced computer vision techniques, this system aims to accurately detect and track steel rods in real-time from video feeds, thereby enhancing operational efficiency, reducing human error, and improving the overall workflow in the steel manufacturing and distribution sectors.

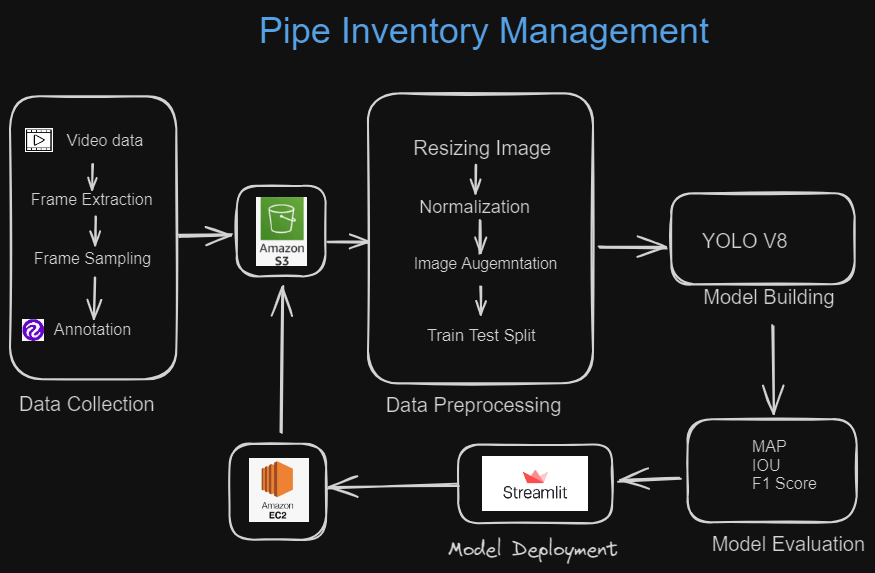

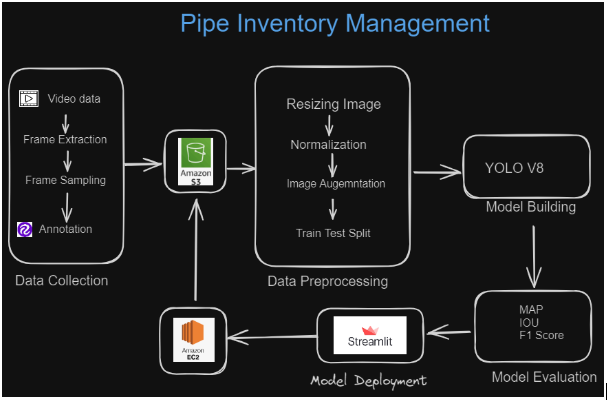

The manual process of counting and categorizing iron pipes based on their dimensions and thickness is a significant operational challenge for one of the leading iron pipes manufacturers. This cumbersome and error-prone process not only drains resources but also impacts the efficiency of inventory management, leading to potential delays in production and distribution.

Problem Statement: In an effort to enhance operational efficiency and streamline inventory management, there's a pressing need for an automated solution capable of accurately detecting and categorizing iron pipes. By employing advanced image processing and machine learning technologies, the project aims to provide a reliable system for real-time identification, counting, and categorization of pipes, thereby reducing manual labor and improving accuracy in inventory records.

A prominent cement manufacturing company in France encounters significant inefficiencies in the distribution of cement bags. The inconsistent storage of cement bags across various locations, coupled with a disconnect between inventory levels and regional demand, exacerbates transportation costs and delivery times. These inefficiencies not only strain the company's logistics but also lead to customer dissatisfaction due to delays in fulfilling orders for high-demand construction projects.

Problem Statement: To address the logistical challenges and align inventory with demand more effectively, the company seeks to optimize its cement bag distribution system. The goal is to minimize transportation costs and delivery times through strategic inventory management and demand forecasting. By doing so, the company aims to enhance customer satisfaction, reduce operational expenses, and maintain its leading position in the French cement market.

The steel manufacturing and distribution industry requires meticulous inventory management, especially with steel rods. Traditional manual counting and diameter measurement methods are both tedious and prone to human error, which can cause operational inefficiencies.

Problem Statement: Introducing an advanced, machine learning-driven system to automatically count and categorize steel rods based on their diameters. This system aims to revolutionize inventory management by boosting accuracy and operational efficiency.

The move towards an automated inventory system signifies a transformative step for the steel manufacturing industry, aiming for operational excellence and a significant boost in profitability.

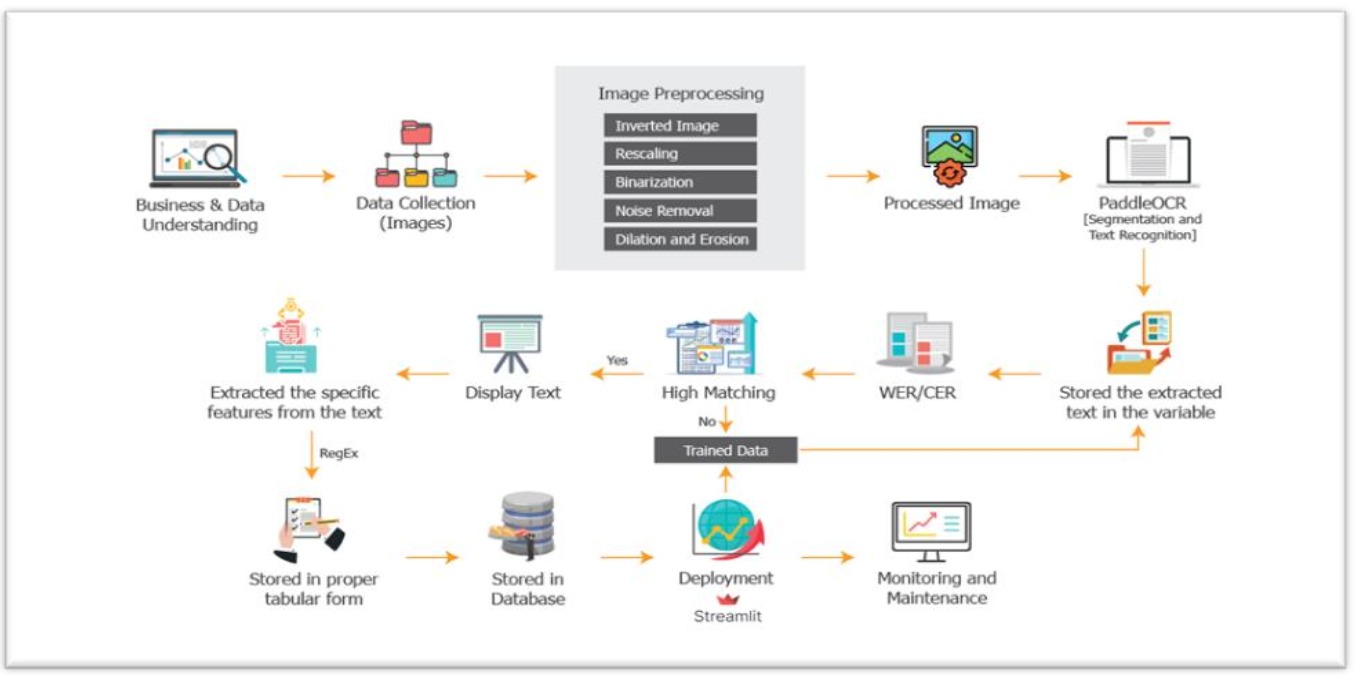

In the fast-paced retail industry, the manual data entry of information from retail store bills into financial management systems is both time-consuming and prone to errors. This inefficient process can lead to inaccuracies in financial records, impacting decision-making and operational efficiency.

Problem Statement: To address the challenges associated with manual invoice processing, this project aims to leverage PaddleOCR, an advanced optical character recognition (OCR) tool, for the automated extraction of text from invoices. By utilizing deep learning models and PaddleOCR's capabilities, the project seeks to significantly reduce the time and effort involved in data entry while enhancing the accuracy and reliability of financial documentation.

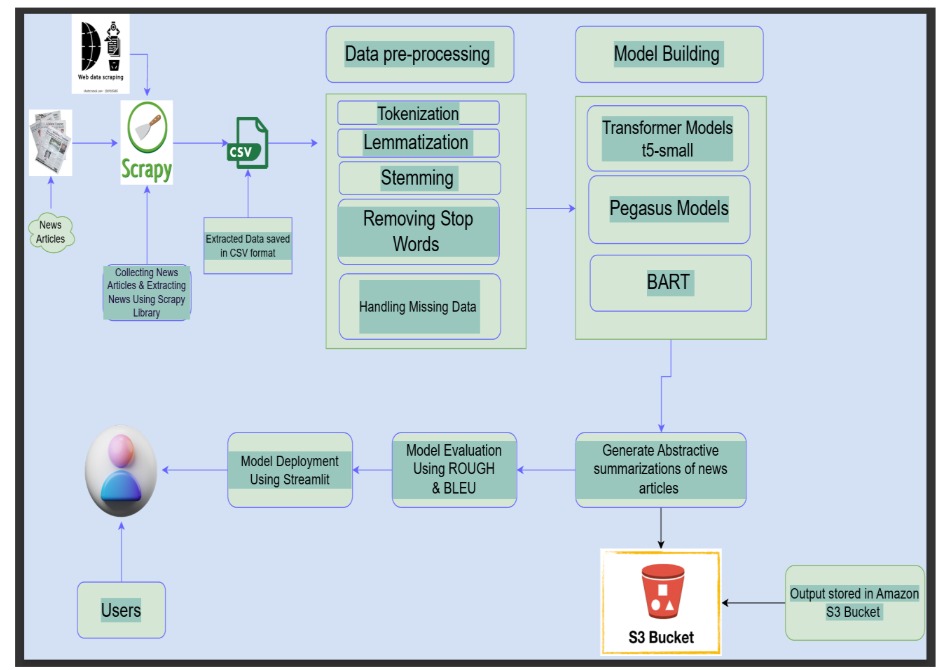

In the fast-paced world of news broadcasting, time is of the essence. A leading news channel in Malaysia faces significant challenges due to the time-consuming process of manually reviewing news articles to write unique, summarized news content. This manual process delays the dissemination of news, affecting the channel's ability to provide timely and concise news updates to its audience.

Problem Statement: To maintain competitiveness and relevance in the news industry, there is a critical need to streamline the process of generating news summaries from existing articles. The project aims to reduce the time and manual effort involved in creating new, summarized articles by implementing an automated system. This system should not only expedite the news writing process but also ensure the accuracy and quality of the content being produced.

Our relentless pursuit of innovation has garnered recognition and profound insights across various domains. Here are some of the pivotal achievements and insights we've derived from our projects:

Recognized the potential of AI in enhancing precision and objectivity in the medical field, particularly IVF, ensuring accurate embryo viability classification.

Transformed inventory management through AI, automating and optimizing processes, as seen in steel rod and egg inventory systems.

Pioneered applications in the automotive sector using AI to detect and rectify sequence anomalies, enhancing quality and safety.

Leveraged machine learning to preemptively detect machine failures in the manufacturing sector, ensuring minimized downtimes and optimized operational efficiency.

Introduced AI-driven solutions to age-old logistics challenges, such as BBS Data Extraction and Pallet Damage Classification.

Detected fraudulent financial activities using AI algorithms, reinforcing the security of the financial ecosystem.

Elevated the education sector with AI innovations like AiTutor, offering data-driven insights for both educators and learners.

Enhanced early detection in healthcare through AI, ensuring improved patient outcomes and potential life-saving interventions.

Engage with the brilliant minds behind our innovations:

Discuss, debate, and share your thoughts on AI trends, innovations, and challenges with our team.

Meet us at tech events, seminars, and workshops. Engage with us as we exhibit, present, and discuss.

Connect with us on LinkedIn to stay abreast of our latest achievements.

Explore our extensive library of research papers and findings.

Experience our innovations first-hand through our POCs.

Understand our solutions deeply through tailored demos and presentations.

Request a Demo Interested in seeing our innovations in action?

Fill out the form below to request a personalized demo tailored to your needs.

Request a Demo!Certainly! If the "See Our Innovations" page is still under development, it's important to convey that to your visitors in a manner that keeps them intrigued and encourages them to return later. Here's a potential message for the under-development page:

We're constantly pushing the boundaries of what's possible in the realm of AI and tech solutions. Our innovation page is under construction as we're curating the very best of our projects and achievements to showcase.

We appreciate your patience and curiosity. Stay tuned for some groundbreaking insights!

Return to Home